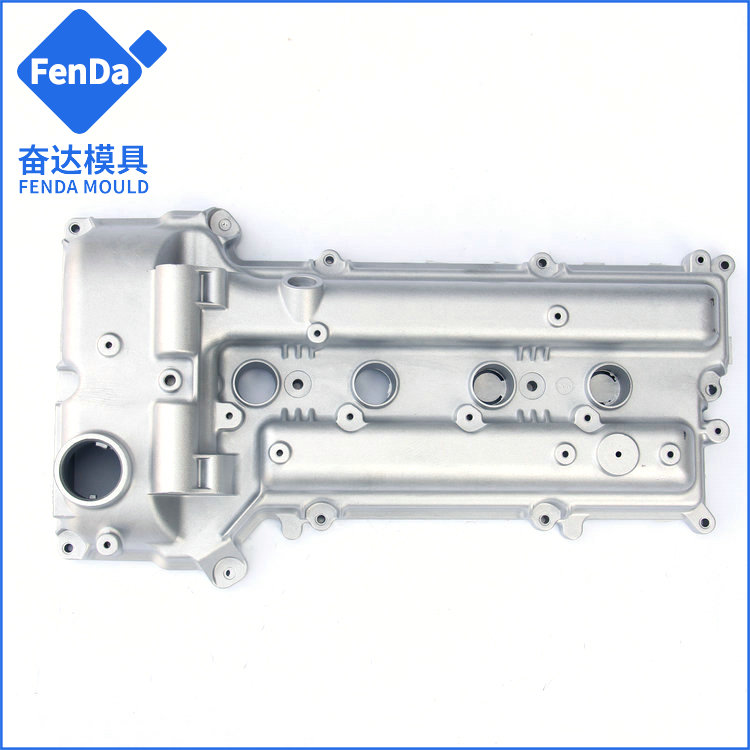

OEM Aluminum Die Cast Auto Parts Engine Housing Cylinder Heads Valve Cover

Fenda Custom Die Casting Parts

| Mold material | H13, DVA, DIEVAR, 8407, 8418, W400, PH13 etc |

| Mold life | 50000 shots , or as per request |

| Product Material | Aluminum alloy ADC12, A360, A380 , AlSi12(Cu), AlSi9Cu3(Fe), AlSi10Mg and so on. |

| Surface Treatment | Polishing, Shotblasting,Sandblasting, Painting, Powder coating |

| Process | Drawing & Samples→Mould making→ Die casting → Deburring → Drilling and threading → CNC Machining → Polishing → Surface treatment → Assembly → Quality inspection → Packing →Shipping |

| Die casting machine | 400T/500T/630T/800T/1250T/1600T/2000T |

| Drawing format | step, dwg, igs, pdf |

| Certificates | ISO/IATF16949 :2016 |

| QC System | 100% inspection before package |

| Monthly Capacity | 40000PCS |

| Lead time | 25~45working days according to quantity |

| Payment terms | T/T |

| Application | Automotive parts, Led light housing & heat sink , Electronic products body, Telecom chasis,cover, Power tool parts , Aerospace structure parts, Aluminum cooling plate, Heat sinks . |

Factory Profile

Fenda, a China-based aluminum die casting manufacturer, offers high-quality products in die casting manufacturing industry. From tooling design to casting parts manufacturing, CNC machining, finishing, and packaging, we provide comprehensive and cost-effective solutions for all your aluminum die casting needs.

- 1-Stop precision aluminum die casting solution provider

- 15+ years of experience, & 140 employees

- ISO 9001 & IATF 16949 certified

- 7 Die casing machines from 400T to 2000T.

- 80+ high-speed/high-precision machining centers

- 30 sets of high-precision stir friction welding、surface treatment and other precision special machines

- 1 set of Zeiss CMM , 1 set of Eduard CMM, 1 set of industrial CT, 1 set of Oxford-Hitachi spectrometer and several sets of gas tightness testers.

CYLINDER HEAD COVER

Our engine cylinder head cover is made of aluminum alloy. In general, aluminum alloy is lighter and has stronger heat dissipation potential than any other material. Meanwhile, Why choose aluminum alloy to be the material of cylinder head valve cover? Not only aluminum cylinder head cover can reduce the weight of the car, but also improve the heat dissipation effect of the engine. Cylinder head covers serve to seal off the cylinder head space from the outside of the engine. As a result of operation of the internal combustion engine, blow-by gases from the combustion process and oil droplets from the lubricant system of the engine are present inside the cylinder head.

A cylinder head is usually located on the top of the engine block. It serves as a housing for components such as the intake and exhaust valves, springs and lifters and the combustion chamber

Why Choose Us For Your Aluminum Die Casting Parts ?

1.High quality

As a factory in aluminum die casting for over 17 years with certificates like ISO9001:2008, IATF16949:2016 etc., Fenda implements the strict procedures in daily production. All products are fully inspected or constructed in accordance with the standards. Testing equipment includes: spectrometer, stretching Testing machine, CMM three-coordinate, pass-stop gauge, parallel gauge, various calipers, etc., to achieve the control ability of the quality system.

2.Die-casting Ability

Fenda is professional manufacturer with the ability to expand the die casting range, with die casting machines of 400-2000 tons of different tonnage. It can produce parts weighing 5g-40kg. The independent furnace of each die casting machine enables us to provide a variety of aluminum to meet the unique needs of customers.

3. CNC Machining Ability

Fenda has an experienced and mature CNC machining team, more than 80 sets of high-speed/high-precision machining centers, and more than 20 sets of high-precision stir friction welding、surface treatment and other precision special machines . It provides reliable precision for processing. The minimum tolerance is controlled by 0.02mm to meet the needs of parts.

4. Most Competitive Price

We believe future development is based on any possible cooperation today, no matter how big the order is. Therefore, we control the profit at a very limited level.

We believe the future development lies in the current cooperation.

Our target is to produce high quality goods with very limited profit margin for the mutual benefits of both of us.

5.Fully Customizable

We follow your specifications on how you want your parts produced, considering your desired dimensions, material, and surface finish. We believe that developing a custom product makes your product unique and puts you ahead of the competition.