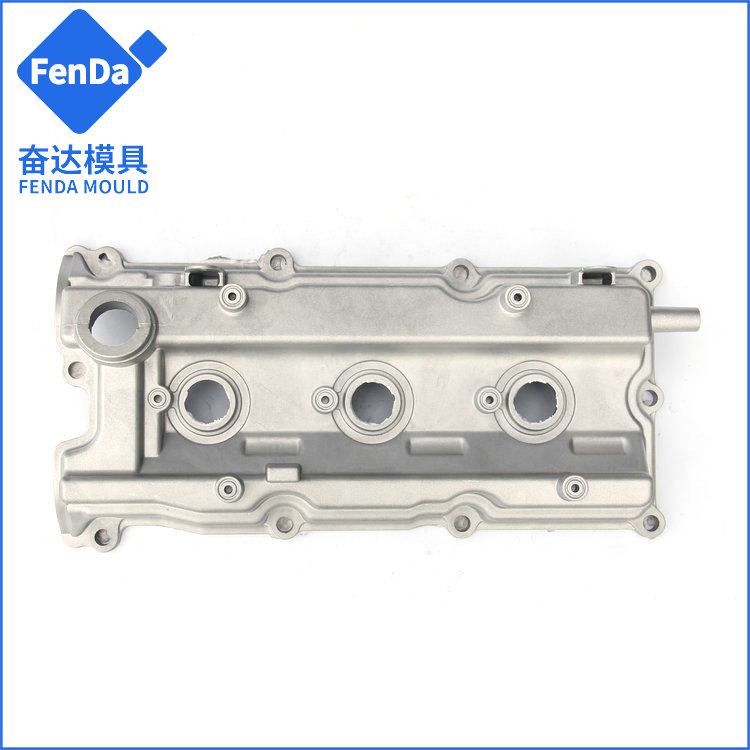

OEM Aluminum Automotive Engine Part Die Casting Cylinder Head Housing /Cover

Fenda Aluminum Die Casting Parts :

| Main Process | High Pressure Die Casting |

| Drawing format | AD, PDF, STP, DWG or Sample |

| Die casting machine type | From 400T to 2000T cold chamber horizontal die cast machines |

| Casting blanks tolerance | CT4-6 |

| Casting blank size | 2 mm-1500mm or according to customer requirements |

| Die casting materials | aluminum alloy, A360, A380, A383, AlSi10Mg, AlSi9Cu3, ADC3 and ADC12, or Customized |

| CNC machining | CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ stir friction welding |

| Machining Tolerance | 0.02MM |

| Machined surface quality | Ra 0.8-Ra3.2 according to customer requirement |

| Surface treatment | Polishing, Shot blasting, Sand blasting, Powder coating etc |

| Product application | Automotive Industry, Led lighting, Telecommunication, Textile machinery, Furniture, Power tool, other machinery industries. |

Our advantage of Aluminum Die Casting

1. Close Tolerance

Our castings are made in metal molds so dimensional variation from piece to piece is negligible and close tolerance is consistently held. Our ability to achieve the highest accuracy and precision has allowed us to successfully cast many parts that have been used without machining, resulting in remarkable savings for our customers.

2. High Quality

Process control and upfront engineering are the keys to guaranteeing high-quality castings. This is probably why Fenda exceeds the industry standards for internal scrap and failure rates. In summary, Fenda strives for Zero-Defects by continuously monitoring all processing and investing painstaking effort into tooling development and designs.

3. Complex Shapes

Our molds are machined out of blocks of high-grade steel. As evidenced by the casting above, complex shapes with thin walls can be cast using ingenious coring techniques so no machining is needed. Undercuts are routinely cast with the use of sand cores, and sometimes, even without. Fully machined cavities, intricate coring techniques, and state-of-the-art molding make complex aluminum parts a routine task for Fenda.

4. Mold Design and Manufacturing in house

The in-house tooling shop allows us to do the die-casting mold design, mold Fabrication & mold maintenance in the same workshop. Our mold engineers will review your drawings and propose suggestions by mold flow analysis, which can help you prevent potential issues or risks that may happen in later production.

Factory Profile

Fenda, a China-based aluminum die casting manufacturer, offers high-quality products in die casting manufacturing industry. From tooling design to casting parts manufacturing, CNC machining, finishing, and packaging, we provide comprehensive and cost-effective solutions for all your aluminum die casting needs.

- 1-Stop precision aluminum die casting solution provider

- 15+ years of experience, & 140 employees

- ISO 9001 & IATF 16949 certified

- 7 Die casing machines from 400T to 2000T.

- 80+ high-speed/high-precision machining centers

- 30 sets of high-precision stir friction welding、surface treatment and other precision special machines

- 1 set of Zeiss CMM , 1 set of Eduard CMM, 1 set of industrial CT, 1 set of Oxford-Hitachi spectrometer and several sets of gas tightness testers.

A cylinder head is usually located on the top of the engine block. It serves as a housing for components such as the intake and exhaust valves, springs and lifters and the combustion chamber