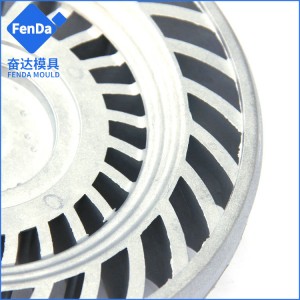

OEM Aluminum Alloy LED Street Light Die Casting Housing Die Cast Products

Fenda Aluminum Alloy Die Casting & CNC

| Process

|

Drawing & Samples→Mould making→ Die casting → Deburring → Drilling and threading → CNC Machining → Polishing → Surface treatment → Assembly → Quality inspection → Packing →Shipping |

| Equipment | Cold chamber horizontal die casting machines 400T--2000T. CNC centers, EDM, WEDM, high-precision stir friction welding machine, CNC Milling machine ,CNC Drilling machine, CNC turning machine, CNC grinding machine,

CMM, Oxford-Hitachi spectrometer, Gas tightness tester |

| Material | Aluminum alloy ADC12, A360, A380 , AlSi12(Cu), AlSi9Cu3(Fe), AlSi10Mg and so on. |

| Surface | Trimming,Deburring,Polishing, Shotblasting,Sandblasting, Painting, Powder coating |

| Software Assistance | Pro-e/Solid work/UG/Auto CAD/CATIA |

| Product application | Automotive Industry, Led lighting, Telecommunication, Textile machinery, Furniture, Power tool, other machinery industries. |

Fenda Aluminum Die Casting Advantage

1.Mold Design and Manufacturing in house

The in-house tooling shop allows us to do the die-casting mold design, mold Fabrication & mold maintenance in the same workshop.

Our mold engineers will review your drawings and propose suggestions by mold flow analysis, which can help you prevent potential issues or risks that may happen in later production.

2.Die-casting Ability

Fenda is professional manufacturer with the ability to expand the die casting range, with die casting machines of 400-2000 tons of different tonnage. The independent furnace of each die casting machine enables us to provide a variety of aluminum to meet the unique needs of customers.

3.ISO Certified and IATF 16949 Certified

Fenda is ISO 9001 certified and IATF16949:2016 certified manufacturing company. We ensure you always receive high-quality automotive parts regardless of design complexity. Furthermore, we guarantee that we develop your products using internationally recognized best practices and that it meets all the required standards.

4.CNC Machining Ability

We offer expert CNC machining services for diverse materials and complex parts. We ensure high precision in rapid prototyping and low-volume manufacturing.

5.Surface Treatment Ability

Fenda can complete the physical surface treatment and powder spraying treatment such as shot blasting, fine sand, powder coating and so on. At the same time, Fenda has been deeply involved in the local supply chain for more than 17 years, strategically integrating dozens of chemical surface treatment suppliers, and through the management of complex supply chains, to provide customers with surface treatment such as plastic spraying, painting, anodizing, electrophoresis, chrome plating, etc.

6. Quality Inspection System

Fenda pays special attention to the quality control of the mass production process and has established a complete quality inspection process and system. All products are fully inspected or constructed in accordance with the standards. Testing equipment includes: spectrometer, stretching Testing machine, CMM three-coordinate, pass-stop gauge, parallel gauge, various calipers, etc., to achieve the control ability of the quality system.