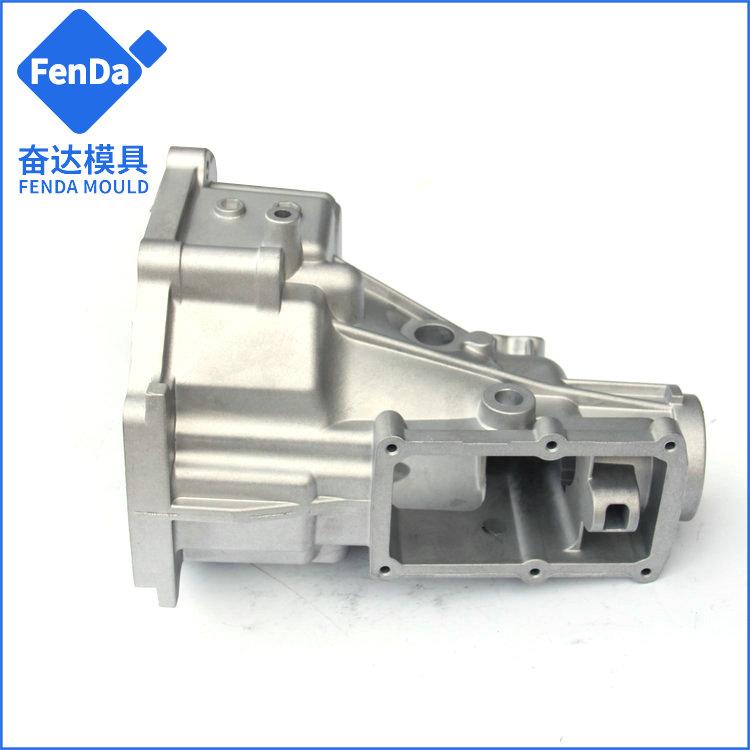

OEM Aluminum Alloy Die Casting Factory Customized Die Cast Auto Transmission Case / Casing Gearbox Housing

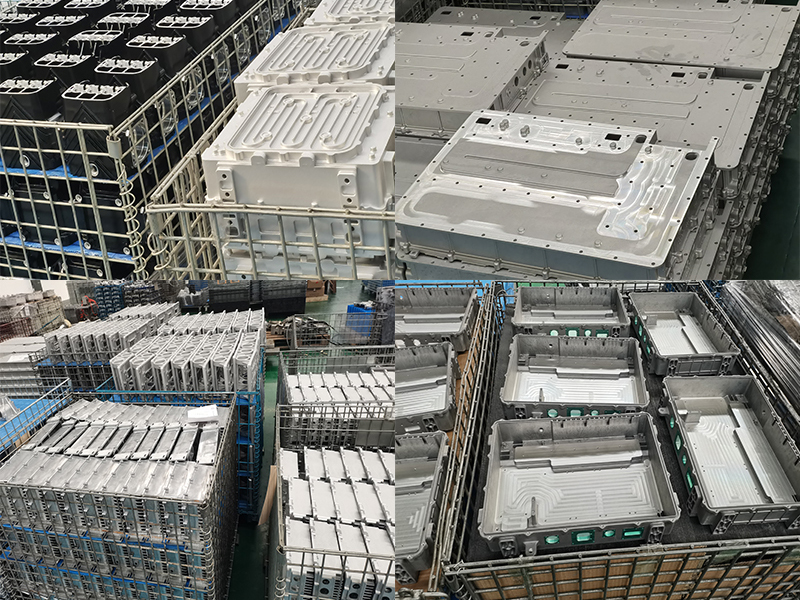

Factory Profile

Focus on design and manufacturing of aluminum die casting molds、 Aluminum alloy die casting and CNC machining.

Founded in 2006.

15000 square meters of plant land area.

More than 30 technicians and engineers.

4 sets of EDM machines, 4 sets of WEDM machines.

6 sets of cold chamber die casting machines ranging from 400T to 2000T.

80 sets of high-speed/high-precision machining centers.

30 sets of high-precision stir friction welding、surface treatment and other precision special machines

1 set of Zeiss CMM , 1 set of Eduard CMM, 1 set of industrial CT, 1 set of Oxford-Hitachi spectrometer and several sets of gas tightness testers.

Our Parts Manufacturing Advantage

1.Mold Design and Manufacturing in house

Our molds are processed independently, without additional profit, moderate cost, short cycle, and sample out at the fastest 35 days, and all our company's ex-factory die-casting parts and unqualified products are returned and exchanged unconditionally.

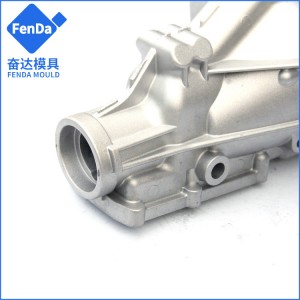

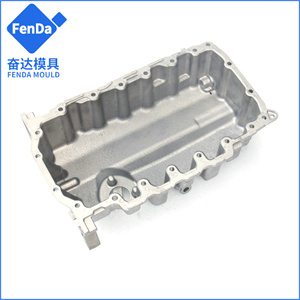

2.Die-casting Ability

Fenda is professional manufacturer with the ability to expand the die casting range, with die casting machines of 400-2000 tons of different tonnage. It can produce parts weighing 5g-20kg. The independent furnace of each die casting machine enables us to provide a variety of aluminum to meet the unique needs of customers.

3. CNC Machining Ability

Fenda has an experienced and mature CNC machining team, more than ten imported processing centers and lathes, and its own processing brand PTJ Shop is one of the top ten small and medium-sized processing manufacturers in China. It provides reliable precision for processing. The minimum tolerance is controlled by 0.02mm to meet the needs of parts.

4. Surface Treatment Ability

Fenda can complete the physical surface treatment and powder spraying treatment such as shot blasting, fine sand, powder coating and so on. At the same time, Fenda has been deeply involved in the local supply chain for more than 17 years, strategically integrating dozens of chemical surface treatment suppliers, and through the management of complex supply chains, to provide customers with surface treatment such as plastic spraying, painting, anodizing, electrophoresis, chrome plating, etc.

5. Quality Inspection System

Fenda pays special attention to the quality control of the mass production process and has established a complete quality inspection process and system. Five tools are commonly used: PPAP, APQP, PFMEA, SPC, and MSA. All products are fully inspected or constructed in accordance with the standards. Testing equipment includes: spectrometer, stretching Testing machine, CMM three-coordinate, pass-stop gauge, parallel gauge, various calipers, etc., to achieve the control ability of the quality system.