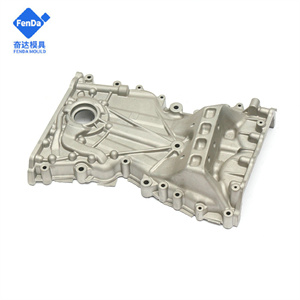

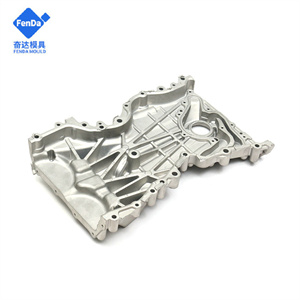

Customized Aluminum Die Casting Shell Engine Part Oil Pump Shell for Automotive

Fenda Aluminum Alloy Die Casting

| Process

|

Drawing & Samples→Mould making→ Die casting → Deburring → Drilling and threading → CNC Machining → Polishing → Surface treatment → Assembly → Quality inspection → Packing →Shipping

|

| Equipment | Cold chamber horizontal die casting machines 400T--2000T. CNC centers, EDM, WEDM, high-precision stir friction welding machine, CNC Milling machine ,CNC Drilling machine, CNC turning machine, CNC grinding machine,

CMM, Oxford-Hitachi spectrometer, Gas tightness tester |

| Material | Aluminum alloy ADC12, A360, A380 , AlSi12(Cu), AlSi9Cu3(Fe), AlSi10Mg and so on. |

| Surface | Trimming,Deburring,Polishing, Shotblasting,Sandblasting, Painting, Powder coating |

| Software Assistance | Pro-e/Solid work/UG/Auto CAD/CATIA |

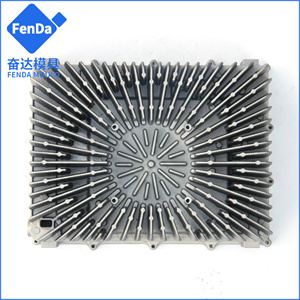

| Product application | Automotive Industry, Led lighting, Telecommunication, Textile machinery, Furniture, Power tool, other machinery industries. |

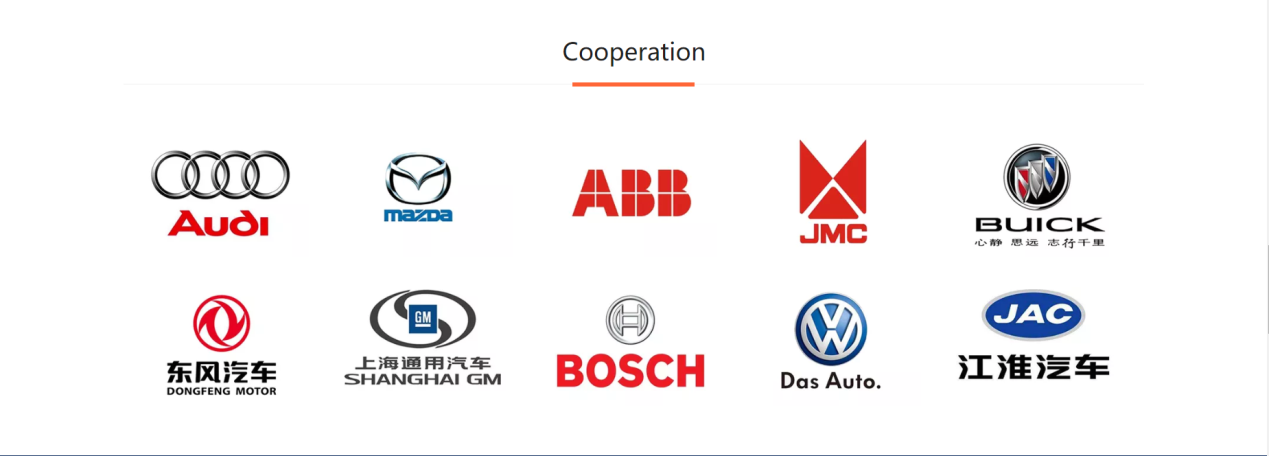

Factory Profile

Fenda, Founded in 2006, a China-based aluminum die casting manufacturer, offers high-quality products in die casting manufacturing industry. From tooling design to casting parts manufacturing, CNC machining, finishing, and packaging, we provide comprehensive and cost-effective solutions for all your aluminum die casting needs.

●1-Stop precision aluminum die casting solution provider

●15+ years of experience, & 140 employees

●ISO 9001 & IATF 16949 certified

●7 Die casing machines from 400T to 2000T.

●80+ high-speed/high-precision machining centers

●30 sets of high-precision stir friction welding、surface treatment and other precision special machines

●1 set of Zeiss CMM , 1 set of Eduard CMM, 1 set of industrial CT, 1 set of Oxford-Hitachi spectrometer and several sets of gas tightness testers.

The Quality Control:

In order to assure the quality of the orders, we assign QC members to carry out strict inspection at each stage:

(1)Incoming material inspection

(2)Inspection of work-in-progress

(3)Finished product inspection

(4)Random warehouse inspections

All of our operations are strictly compliant with ISO 9001: 2008 guidelines

We own automated casting lines, CNC machining, CMM inspection, spectrometers and MT testing equipment, X-ray.

To benefit from our strong OEM/ODM capabilities and considerate services, contact us today.

We will sincerely create and share success with all clients.

Efficient

Our die cast machines work 24/7/360 without stop, which means we can fulfill your bulk order in a shorter period of time.