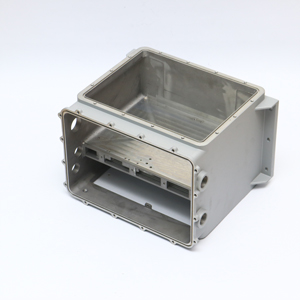

Customized Aluminum Die Cast Shell Motor Controller Housing Die Casting for Electric Vehicle

Product Description

| Product Name: | OEM Electric Vehicle Motor Controller Shell |

| Material; | ADC12 |

| Specification: | to Customized |

| Precision Machining; | CNC machining |

| Tolerance; | 0.02mm |

| Inspection: | CMM, Oxford-Hitachi spectrometer, Calipers etc |

| Surface Finishing | Deburring +Sandblasting |

| Application: | New Energy Car or New Energy Bus |

| Certification: | ISO9001/IATF16949:2016 |

Factory Profile

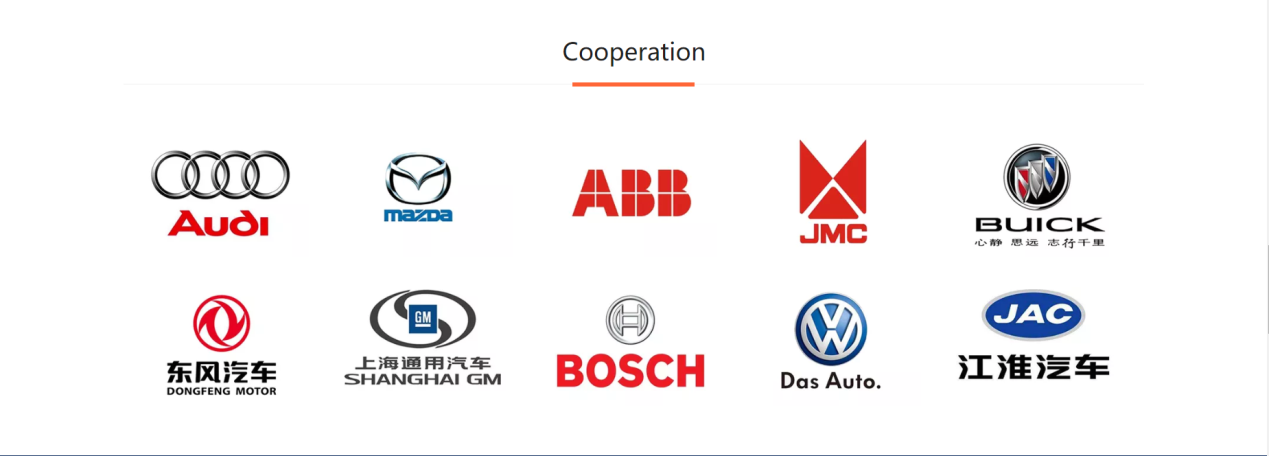

Fenda, a China-based aluminum die casting manufacturer, proudly offers high-quality products in die casting manufacturing industry. From tooling design to casting parts manufacturing, CNC machining, finishing, and packaging, we provide comprehensive and cost-effective solutions for all your aluminum die casting needs.

●1-Stop precision aluminum die casting solution provider

●15+ years of experience, & 140 employees

●ISO 9001 & IATF 16949 certified

●7 Die casing machines from 400T to 2000T.

●80+ high-speed/high-precision machining centers

●30 sets of high-precision stir friction welding、surface treatment and other precision special machines

●1 set of Zeiss CMM , 1 set of Eduard CMM, 1 set of industrial CT, 1 set of Oxford-Hitachi spectrometer and several sets of gas tightness testers.

With turn-key solutions, a team of experts, and a commitment to delivering superior-quality products and services, we help you save costs and run your projects more smoothly. Contact us for your next project.

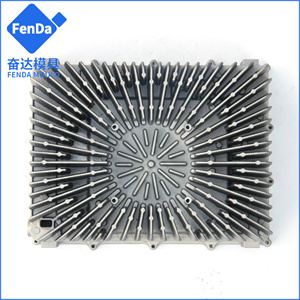

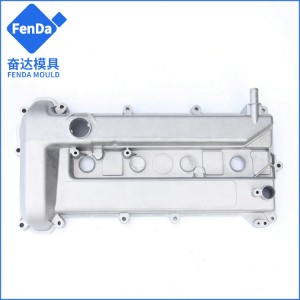

Fenda Aluminum Die Casting Parts :

| Main Process | High Pressure Die Casting |

| Drawing format | AD, PDF, STP, DWG or Sample |

| Die casting machine type | From 400T to 2000T cold chamber horizontal die cast machines |

| Casting blanks tolerance | CT4-6 |

| Casting blank size | 2 mm-1500mm or according to customer requirements |

| Die casting materials | aluminum alloy, A360, A380, A383, AlSi10Mg, AlSi9Cu3, ADC3 and ADC12, or Customized |

| CNC machining | CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ stir friction welding |

| Machining Tolerance | 0.02MM |

| Machined surface quality | Ra 0.8-Ra3.2 according to customer requirement |

| Surface treatment | Polishing, Shot blasting, Sand blasting, Powder coating etc |

Why Choose Fenda For Your Aluminum Die Casting Parts ?

1.Mold Design and Manufacturing in house

The in-house tooling shop allows us to do the die-casting mold design, mold Fabrication & mold maintenance in the same workshop. Our mold engineers will review your drawings and propose suggestions by mold flow analysis, which can help you prevent potential issues or risks that may happen in later production.

2.Die-casting Ability

Fenda is professional manufacturer with the ability to expand the die casting range, with die casting machines of 400-2000 tons of different tonnage. It can produce parts weighing 5g-40kg. The independent furnace of each die casting machine enables us to provide a variety of aluminum to meet the unique needs of customers.

3. CNC Machining Ability

Fenda has an experienced and mature CNC machining team, more than ten imported processing centers and lathes, and its own processing brand PTJ Shop is one of the top ten small and medium-sized processing manufacturers in China. It provides reliable precision for processing. The minimum tolerance is controlled by 0.02mm to meet the needs of parts.

4.Most Competitive Price

We believe future development is based on any possible cooperation today, no matter how big the order is. Therefore, we control the profit at a very limited level.

We believe the future development lies in the current cooperation.

Our target is to produce high quality goods with very limited profit margin for the mutual benefits of both of us.

5.High quality

As a factory in aluminum die casting for over 17 years with certificates like ISO9001:2008, IATF16949:2016 etc., Fenda implements the strict procedures in daily production. All products are fully inspected or constructed in accordance with the standards. Testing equipment includes: spectrometer, stretching Testing machine, CMM three-coordinate, pass-stop gauge, parallel gauge, various calipers, etc., to achieve the control ability of the quality system.