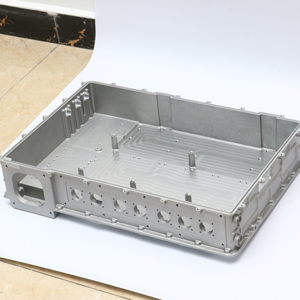

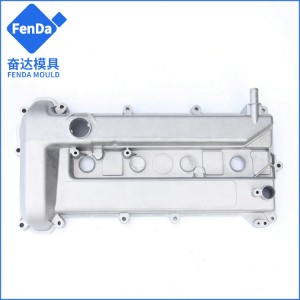

Customized Aluminum Die Cast Part Auto Engine Housing Oil pump housing Motor Shell

Factory Profile

Ningbo Fenda New Energy Technology Co., Ltd ( IATF 16949 registered factory), was established in 2006 with 15,000 square meters manufacturing facility. Located in Ningbo, China , it is dedicated to designing and manufacturing medium and large aluminum die casting molds and die castings for the Automotive, LED Lighting housing, Power Tools, and numerous mechanical applications. Our capabilities include tool design and manufacturing; casting; machining; finishing and assembly. As a member of China Die Casting Association, our annual capacity for mold is 200 sets and annual capacity for die castings are over 1500 tons.

With hard work, outstanding quality, and dependable service we have successfully and steadily grown over the years and have survived good and bad economic times along the way. Our main customers include ABB , GM, AUDI,MAZDA , BOSCH, BUICK and so on. For these customers we have designed and manufactured over hundreds sets of moulds these years. Most of our products have exported to USA, Germany, Italy, U.K., Netherlands and so on.

Why Choose Us For Your Aluminum Die Casting Parts ?

1.High quality

As a company in aluminum die casting for over 17 years with certificates like ISO9001:2008, IATF16949:2016 etc., Fenda implements the strict procedures in daily production. All products are fully inspected or constructed in accordance with the standards. Testing equipment includes: spectrometer, stretching Testing machine, CMM three-coordinate, pass-stop gauge, parallel gauge, various calipers, etc., to achieve the control ability of the quality system.

2. Most Competitive Price

We believe future development is based on any possible cooperation today, no matter how big the order is. Therefore, we control the profit at a very limited level.

We believe the future development lies in the current cooperation.

Our target is to produce high quality goods with very limited profit margin for the mutual benefits of both of us.

3. Fast delivery

With our instant quotation system coupled with the perfect combination of advanced technology and top-draw professionals, Fenda produces and delivers your die casting parts as fast as possible. Our die cast machines work 24/7/365 without stop, which means we can fulfill your bulk order in a shorter period of time

4. Strict Quality Control

In order to assure the quality of the orders, we assign QC members to carry out strict inspection at each stage:

(1)Incoming material inspection

(2)Inspection of work-in-progress

(3)Finished product inspection

(4)Random warehouse inspections

All of our operations are strictly compliant with ISO 9001: 2008 guidelines

We own automated casting lines, CNC machining, CMM inspection, spectrometers and MT testing equipment, X-ray.

To benefit from our strong OEM/ODM capabilities and considerate services, contact us today.

We will sincerely create and share success with all clients.

5.Fully Customizable

We follow your specifications on how you want your parts produced, considering your desired dimensions, material, and surface finish. We believe that developing a custom product makes your product unique and puts you ahead of the competition.