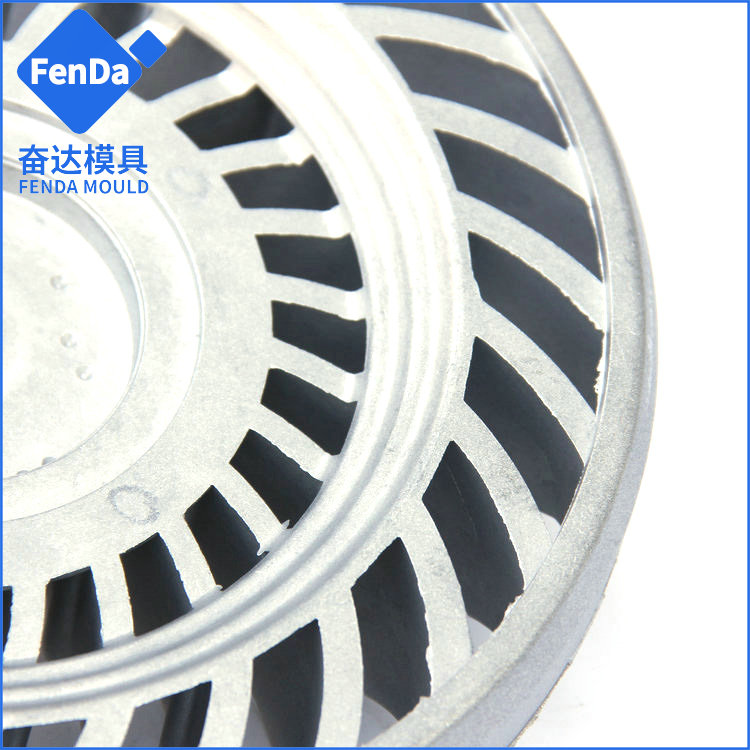

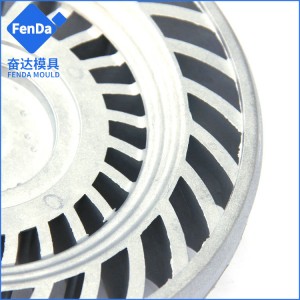

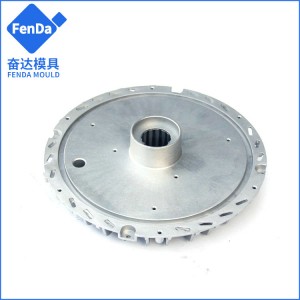

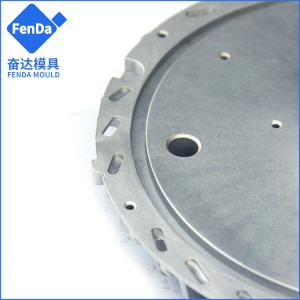

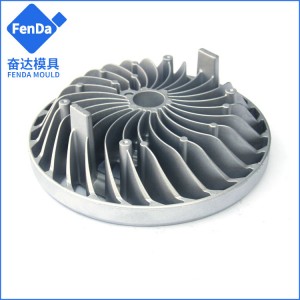

Customized Aluminum Alloy Die Cast Led Lamp Heat sink Light Housing Die Casting

Product Description

| Product Name: | Led light heat sink |

| Material: | ADC12 |

| Specification: | To Be Customized |

| Certification | ISO9001/IATF16949:2016 |

| Application: | LED Lighting |

| Crafts | Aluminum High Pressure die casting + CNC machining |

| Surface | Deburring + Sand Blasting |

| Inspection | CMM, Calipers etc |

Features of Die Cast Heat Sink

High pressure die cast heat sinks are a cost effective alternative for high volume applications, the features are:

Metal parts with complex shapes, clear contours and thin-walled deep cavities can be manufactured. Because the molten metal maintains high mobility in high pressure and high speed, it can produce metal parts which other process can’t

High dimensional accuracy, up to IT11-13, sometimes up to IT9, surface roughness of Ra0.8-3.2um, good interchangeability.

High material utilization. Due to the high precision of die-casting, only a small amount of machining is needed, some die-casting can be directly assembled and used. Its material utilization rate of about 60% – 80%, the utilization rate of the blank up to 90%.

High production efficiency. Due to the high-speed filling, short filling time, metal also solidified quickly, fast operation cycle speed, die-casting has the highest productivity, suitable for mass production.

FACTORY PROFILE

Fenda, a China-based aluminum die casting manufacturer, proudly offers high-quality products in die casting manufacturing industry. From tooling design to die casting parts manufacturing, finishing, and packaging, we provide comprehensive and cost-effective solutions for all your aluminum die casting needs.

1-Stop precision aluminum die casting solution provider.

17+ years of experience, 15000 square meters plant & 140 employees.

ISO 9001 & IATF16949 certificated.

4 sets of EDM machines, 4 sets of WEDM machines.

7 sets of cold chamber die casting machines ranging from 400T to 2000T.

80 sets of high-speed/high-precision machining centers.

30 sets of high-precision stir friction welding、surface treatment and other precision special machines

1 set of Zeiss CMM , 1 set of Eduard CMM, 1 set of industrial CT, 1 set of Oxford-Hitachi spectrometer and several sets of gas tightness testers.

With turnkey solutions, a team of experts, and a commitment to delivering superior-quality products and services, we help you save costs and run your projects more smoothly. Contact us with your next project.