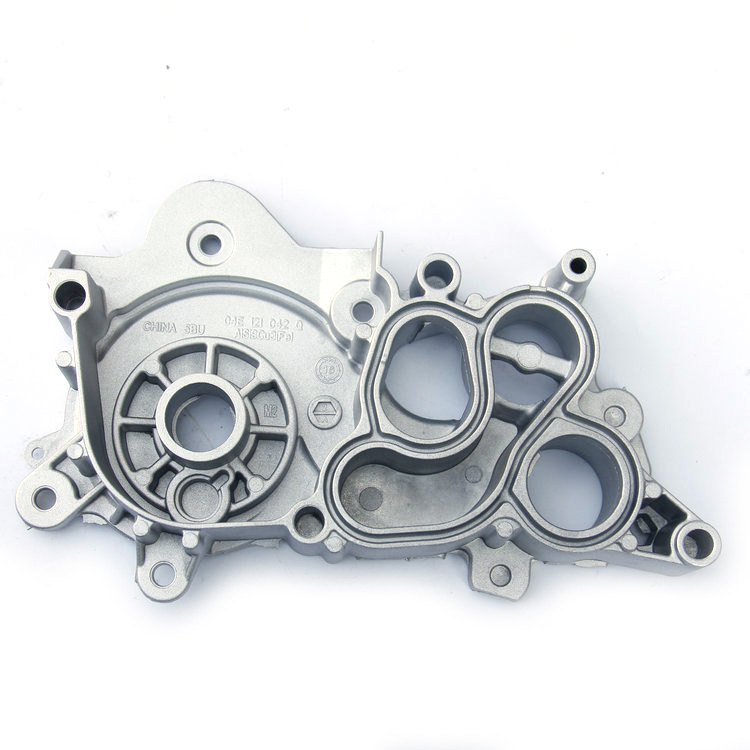

Custom Aluminum High Pressure Die Casting Products Water Pump Housing /Enclosure/Casing/Case for Automotive Diecast Parts

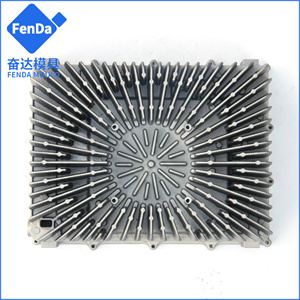

Fenda Custom Aluminum Die Casting Parts

| Product Material | Aluminum alloy ADC12, A360, A380 , AlSi12(Cu), AlSi9Cu3(Fe), AlSi10Mg and so on. |

| Surface Treatment | Polishing, Shotblasting,Sandblasting, Painting, Powder coating |

| Process | Drawing & Samples→Mould making→ Die casting → Deburring → Drilling and threading → CNC Machining → Polishing → Surface treatment → Assembly → Quality inspection → Packing →Shipping |

| Die casting machine | 400T/500T/630T/800T/1250T/1600T/2000T |

| Drawing format | step, dwg, igs, pdf |

| Certificates | ISO/TS16949 :2016 |

| QC System | 100% inspection before package |

| Monthly Capacity | 40000PCS |

| Lead time | 25~45working days according to quantity |

| Payment terms | T/T |

| Application | 1,Automotive parts

2, LED light housing and LED heat sink 3, Power tool 4,Gas appliance 5,Telecomnunication 6,Furniture accessories 7, Other Mechanical parts |

Factory Profile

Ningbo Fenda New Energy Technology Co., Ltd ( IATF 16949 registered company). was established in 2006 with 15,000 square meters manufacturing facility. Located in Ningbo, China , it is dedicated to designing and manufacturing medium and large aluminum die casting molds and die castings for the Automotive, LED Lighting housing, Power Tools, and numerous mechanical applications. Our capabilities include tool design and manufacturing; casting; machining; finishing and assembly. As a member of China Die Casting Association, our annual capacity for mold is 200 sets and annual capacity for die castings are over 1500 tons.

With hard work, outstanding quality, and dependable service we have successfully and steadily grown over the years and have survived good and bad economic times along the way. Our main customers include ABB , GM, AUDI,MAZDA , BOSCH, BUICK and so on. For these customers we have designed and manufactured over hundreds sets of moulds these years. Most of our products have exported to USA, Germany, Italy, U.K., Netherlands and so on.