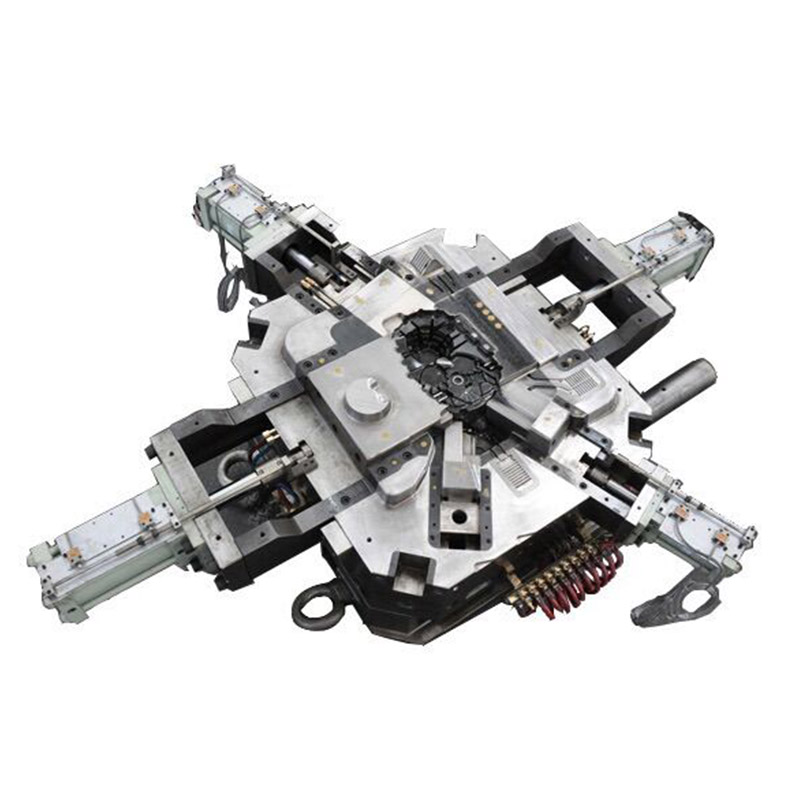

Custom Aluminum Die Casting Mold Factory of Auto Parts Gearbox Housing Automotive Parts Die Cast Tooling

Basic Information

|

Product name |

High Pressure Die Casting Auto Gearbox Housing Mold |

|

Mould Material |

PH13,H13, DVA, DIEVAR, 8407, 8418, W400 etc |

|

Casting Alloy |

Aluminum |

|

Cavity Qty |

Single Cavity, Multiple Cavity or Combination Cavity |

|

Tonnage |

200T-2000T |

|

Treatment |

Heat Treatment, Nitriding, Polishing etc. |

|

Mold Life |

30000 shots,50000 shots, 80000shots depend on products |

|

Applications |

1. Automobile and motorcycle parts; |

|

2. Lights & lamps parts; |

|

|

3. Electrical appliance parts; |

|

|

4. Telecom Parts; |

|

|

5. Industrial hardware and Machine Sparepart; |

|

|

6. Household Appliance parts; |

|

|

7. Furniture parts; |

|

|

Lead Time |

35-60 days |

|

Special request |

According to customer’s request |

Fenda can customize, but not limited to these:

Aluminum die casting auto part mold

Aluminum die casting telecom housing mold

Aluminum die casting power tools mold

Aluminum die casting power tools housing mold

Aluminum die casting auto gearbox housing mold

Aluminum die casting auto water pump housing mold

Aluminum die casting light housing mold

Including other Aluminum High Pressure Die Casting Tools.

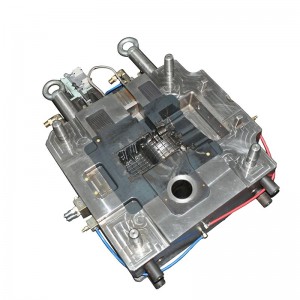

The Fenda Aluminum Die Casting Mold Manufacturing Advantage

When it comes to high-quality custom die casting mold development, several influences contribute to the overall success of the process. Fenda provides custom aluminum die casting mold production services to your project specifications. Fenda delivers the following die casting service advantages:

- First Class Engineering

- Die-cast tools designed in house

- Manage and oversee all aspects of tooling

- Developing injection process parameters: gate size, location, feeding speed, fill time, injection pressure, press size

- Parting line, runner, overflow, venting, cooling

- Minimum and Maximum wall thickness

- Choice of the mold material and hardness based on mold forces calculation

- Superior or Premium Grade H13 or Dievar

- Flow simulation

- Draft, radii, filets

- Establishing machining stock

- Utilization of both domestic and overseas tooling suppliers

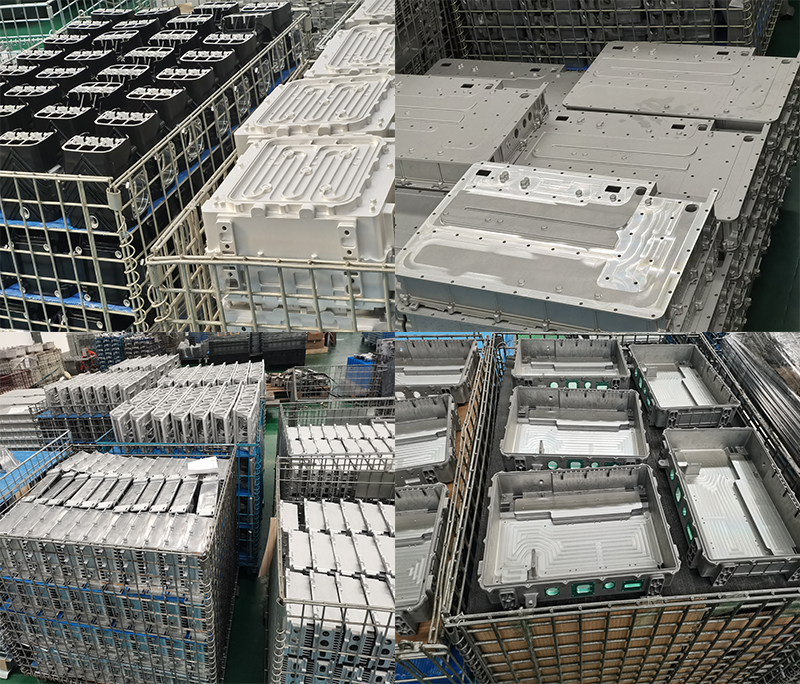

Factory Profile

Fenda, a China-based aluminum die casting manufacturer, proudly offers high-quality products in die casting manufacturing industry. From tooling design to casting parts manufacturing, CNC machining, finishing, and packaging, we provide comprehensive and cost-effective solutions for all your aluminum die casting needs.

- 1-Stop precision aluminum die casting solution provider

- 15+ years of experience, & 140 employees

- ISO 9001 & IATF 16949 certified

- 7 Die casing machines from 400T to 2000T.

- 80+ high-speed/high-precision machining centers

- 30 sets of high-precision stir friction welding、surface treatment and other precision special machines

- 1 set of Zeiss CMM , 1 set of Eduard CMM, 1 set of industrial CT, 1 set of Oxford-Hitachi spectrometer and several sets of gas tightness testers.

With turn-key solutions, a team of experts, and a commitment to delivering superior-quality products and services, we help you save costs and run your projects more smoothly. Contact us for your next project.