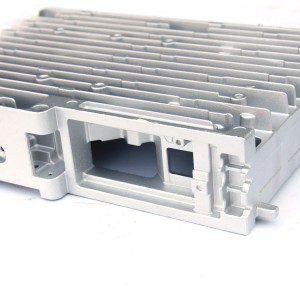

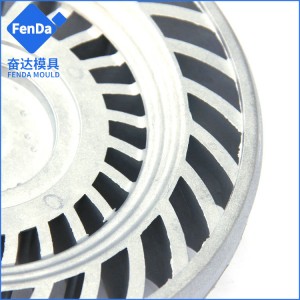

Custom Aluminum Die Casting Housing Enclosure LED Light Housing with Heat Sink

Product Description

| Product Name: | Led light housing with heat sink |

| Material: | ADC12 |

| Specification: | To Be Customized |

| Certification | ISO9001/IATF16949:2016 |

| Application: | LED Lighting |

| Crafts | Aluminum High Pressure die casting + CNC machining |

| Surface | Deburring + Sand Blasting |

| Inspection | CMM, Calipers etc |

Fenda Aluminum Alloy Die Casting

| Mold material | H13, DVA or as per request |

| Mold life | 50000 shots , or as per request |

| Product Material | Aluminum alloy ADC12, A360, A380 , AlSi12(Cu), AlSi9Cu3(Fe), AlSi10Mg and so on. |

| Surface Treatment | Polishing, Shot blasting, Sand blasting, Painting, Powder coating |

| Process | Drawing & Samples→Mould making→ Die casting → Deburring → Drilling and threading → CNC Machining → Polishing → Surface treatment → Assembly → Quality inspection → Packing →Shipping |

| Die casting machine | 400T/500T/630T/800T/1250T/1600T/2000T |

| Drawing format | step, dwg, igs, pdf |

| Certificates | ISO/IATF16949 :2016 |

| QC System | 100% inspection before package |

| Monthly Capacity | 40000PCS |

| Lead time | 25~45working days according to quantity |

| Application | 1,Automotive parts

2, LED light housing and heat sink 3, Power tool 4,Gas appliance 5,Textile machinery 6,Telecomnunication 7,Furniture accessories 8, Other Mechanical parts |

Factory Profile

Fenda is capable of designing and manufacturing tooling and fixtures for all our processes .

Simulation analysis helps our engineers design more efficient tooling. In-housing die casting tooling workshop assists in reaching customer lead time for manufacturing and verification.

The high pressure die casting process best illustrates our level of manufacturing capability. We have 7 advanced cold chamber die casting machines from 400T to 2000T in our die casting workshop, which allows us to meet demands in various aluminum die casting projects.

Our CNC machining center , equipped with 80 sets of high-speed/high-precision machining centers, and more than 20 sets of high-precision stir friction welding、surface treatment and other precision special machines . After machining, we can apply aesthetic ,functional and protective coating

Why Choose Us For Your Aluminum Die Casting Parts ?

1.High quality

As a factory in aluminum die casting for over 17 years with certificates like ISO9001:2008, IATF16949:2016 etc., Fenda implements the strict procedures in daily production. All products are fully inspected or constructed in accordance with the standards. Testing equipment includes: spectrometer, stretching Testing machine, CMM three-coordinate, pass-stop gauge, parallel gauge, various calipers, etc., to achieve the control ability of the quality system.

2. Most Competitive Price

We believe future development is based on any possible cooperation today, no matter how big the order is. Therefore, we control the profit at a very limited level.

We believe the future development lies in the current cooperation.

Our target is to produce high quality goods with very limited profit margin for the mutual benefits of both of us.

3. Fast delivery

With our instant quotation system coupled with the perfect combination of advanced technology and top-draw professionals, Fenda produces and delivers your automotive parts as fast as possible. Getting your products faster will give more flexibility to improve or iterate them, thus outpacing your competitors during rapid shifts in the market

4. 100% Satisfaction Service

Any question regarding products raised by customers will be replied within 24 hours.

For any after-sales complaint, we absolutely shoulders the responsibility to solve it based on customer-oriented solution; this is why our business is skyrocketing.

5.Fully Customizable

We follow your specifications on how you want your parts produced, considering your desired dimensions, material, and surface finish. We believe that developing a custom product makes your product unique and puts you ahead of the competition.