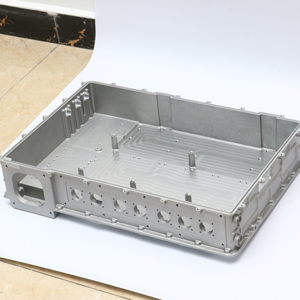

Custom Aluminum Die Casting Automotive Part Vehicle Part Oil Pump Shell Diecast Housing

Precision die casting solutions for the automotive parts

Fenda delivers precision results for the automotive industry. As a trusted partner, we specialize in high pressure aluminum die casting solutions for vehicle components and parts. We have been operating since 2006 and upgraded our facilities in 2020 to accommodate large and complex automotive projects.

Our team has specialized industry knowledge and diverse experience in the transportation and automotive sectors. We specialize in accurate and cost-effective high pressure die casting for demanding automotive applications

Why Choose Us For Your Automotive Parts Projects

Fenda has over 17 years of experience assisting automotive manufacturers design cost-effective automotive components. When you cooperate with Fenda you can receive the following benefits from our die casting process:

The in-house tooling shop allows us to do the die-casting mold design, mold Fabrication & mold maintenance in the same workshop. Our mold engineers will review your drawings and propose suggestions by mold flow analysis, which can help you prevent potential issues or risks that may happen in later production.

Fenda’s die casting operation features 7 presses ranging from 400 to 2000 ton. We also have partner factory with smaller die casting machines. We accommodate some of the most demanding automotive part runs in terms of volume, part size, and complexity. Because of our engineering and modeling capabilities, we are known by our clients as a company that can reduce part complexity, and make the manufacturing process more efficient.

Fenda can help consolidate your supply chain by offering the complete package of die casting services in addition to engineering support, mold design and troubleshooting, machining, and logistics.

Fenda is an ISO Certified and ITAF 16949 certified die Casting Manufacturer and has extensive experience in designing and manufacturing aluminum parts to automotive quality specifications.

With presses ranging from large to small, we have the capability to manufacture automobile parts of many sizes.

Our technology facilitates and streamlines production. Our suite of technology includes AutoCAD, Pro-E, CAD/CAM and EDI compatibility, and FARO Laser Scanning.