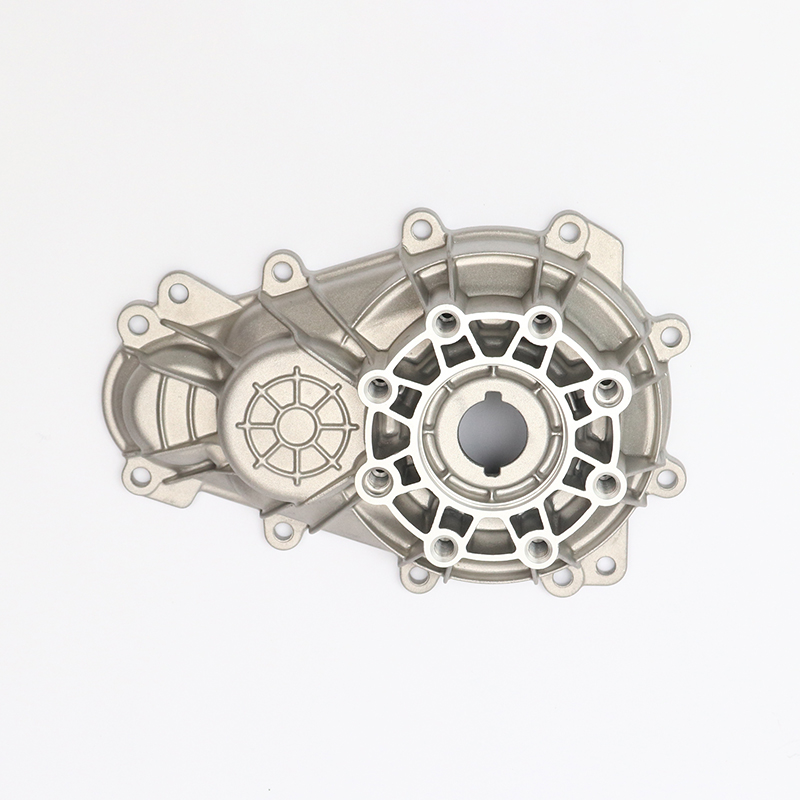

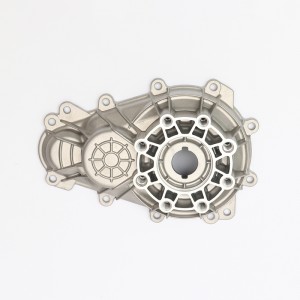

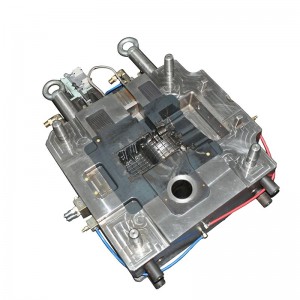

Custom Aluminum Alloy Die Casting parts for Automobile Transmission Housing Case Gearbox Cover

Fenda Aluminum Die Casting Parts

| Mold material | PH13,H13, DVA or as per request |

| Mold life | 50000shots , or as per request |

| Product Material | Aluminum alloy ADC10, ADC12, A360, A380 and as per request |

| Surface Treatment | Polishing, Shotblasting,Sandblasting, Painting, Powder coating |

| Process | Drawing & Samples→Mould making→ Die casting → Deburring → Drilling and threading → CNC Machining → Polishing → Surface treatment → Assembly → Quality inspection → Packing →Shipping |

| Die casting machine | 280T/400T/500T/630T/800T/1250T/1600T/2000T |

| Drawing format | step, dwg, igs, pdf |

| Certificates | ISO/TS16949 :2016 |

| QC System | 100% inspection before packaging |

| Monthly Capacity | 40000PCS |

| Lead time | 25~45working days according to quantity |

| Payment terms | T/T |

| Application | 1,Automotive parts

2, LED light housing and heat sink 3, Power tool 4,Gas appliance 5,Textile machinery 6,Telecomnunication 7,Furniture accessories 8, Other Mechanical parts |

Factory Profile

Focus on design and manufacturing of aluminum die casting molds, Aluminum alloy die casting and CNC machining.

Founded in 2006.

15000 square meters of plant land area.

More than 30 technicians and engineers.

4 sets of EDM machines, 4 sets of WEDM machines.

6 sets of cold chamber die casting machines ranging from 400T to 2000T.

80 sets of high-speed/high-precision machining centers.

30 sets of high-precision stir friction welding、surface treatment and other precision special machines

1 set of Zeiss CMM , 1 set of Eduard CMM, 1 set of industrial CT, 1 set of Oxford-Hitachi spectrometer and several sets of gas tightness testers.