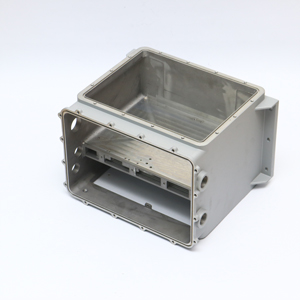

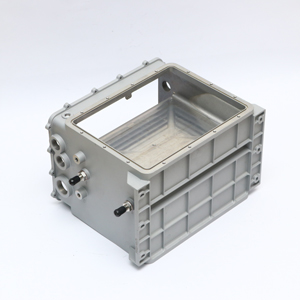

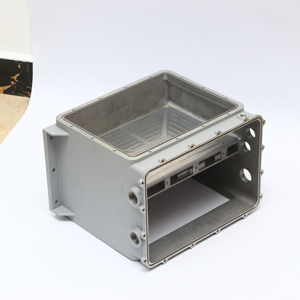

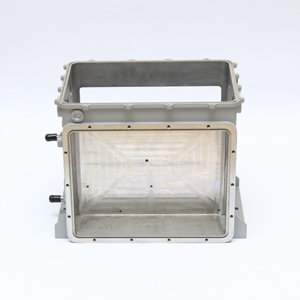

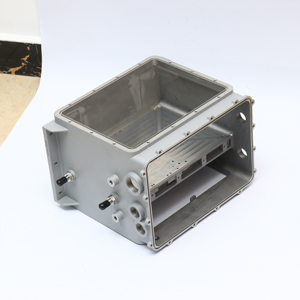

Custom Aluminum Alloy Die Casting Housing/Shell/Enclosure/Casing for Automotive Electric Vehicle Motor Controller Shell

About Electric Vehicle Motor Controller Housing

The motor controller is used to drive the main motor on the electric vehicle. Generally, it receives the signal of the whole vehicle controller to control the starting, running, speed regulating and stopping of the main motor. Together with the whole vehicle controller, it is just like the brain of the electric vehicle being an important part of the electric vehicle. At present, the motor controller is increasingly integrated, including single main drive controller, three-in-one controller (integration: EHPS controller + ACM controller + DC/AC), five-in-one controller (integration: EHPS controller + ACM controller + DC/DC + PDU + dual source EPS controller), passenger car controller (integration: main drive + DC/DC) and other controllers.

Fenda Aluminum Die Casting Parts :

| Main Process | High Pressure Die Casting |

| Drawing format | AD, PDF, STP, DWG or Sample |

| Die casting machine type | From 400T to 2000T cold chamber horizontal die cast machines |

| Casting blanks tolerance | CT4-6 |

| Casting blank size | 2 mm-1500mm or according to customer requirements |

| Die casting materials | aluminum alloy, A360, A380, A383, AlSi10Mg, AlSi9Cu3, ADC3 and ADC12, or Customized |

| CNC machining | CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ stir friction welding |

| Machining Tolerance | 0.02MM |

| Machined surface quality | Ra 0.8-Ra3.2 according to customer requirement |

| Surface treatment | Polishing, Shot blasting, Sand blasting, Powder coating etc |

| Product application | Automotive Industry, Led lighting, Telecommunication, Textile machinery, Furniture, Power tool, other machinery industries. |

Factory Profile

Ningbo Fenda New Energy Technology Co., Ltd ( IATF 16949 registered factory), was established in 2006 with 15,000 square meters manufacturing facility. Located in Ningbo, China , it is dedicated to designing and manufacturing medium and large aluminum die casting molds and die castings for the Automotive, LED Lighting housing, Power Tools, and numerous mechanical applications.

Our capabilities include tool design and manufacturing; casting; machining; finishing and assembly. As a member of China Die Casting Association, our annual capacity for mold is 200 sets and annual capacity for die castings are over 1500 tons.

●1-Stop precision aluminum die casting solution provider

●15+ years of experience, & 140 employees

●ISO 9001 & IATF 16949 certified

●7 Die casing machines from 400T to 2000T.

●80+ high-speed/high-precision machining centers

●30 sets of high-precision stir friction welding、surface treatment and other precision special machines

●1 set of Zeiss CMM , 1 set of Eduard CMM, 1 set of industrial CT, 1 set of Oxford-Hitachi spectrometer and several sets of gas tightness testers.

With turn-key solutions, a team of experts, and a commitment to delivering superior-quality products and services, we help you save costs and run your projects more smoothly. Contact us for your next project.

Why Choose Fenda For Your Aluminum Die Casting Parts ?

The Quality Control:

In order to assure the quality of the orders, we assign QC members to carry out strict inspection at each stage:

(1)Incoming material inspection

(2)Inspection of work-in-progress

(3)Finished product inspection

(4)Random warehouse inspections

All of our operations are strictly compliant with ISO 9001: 2008 guidelines

We own automated casting lines, CNC machining, CMM inspection, spectrometers and MT testing equipment, X-ray.

To benefit from our strong OEM/ODM capabilities and considerate services, contact us today.

We will sincerely create and share success with all clients.

Most Competitive Price

We believe future development is based on any possible cooperation today, no matter how big the order is. Therefore, we control the profit at a very limited level.

We believe the future development lies in the current cooperation.

Our target is to produce high quality goods with very limited profit margin for the mutual benefits of both of us.