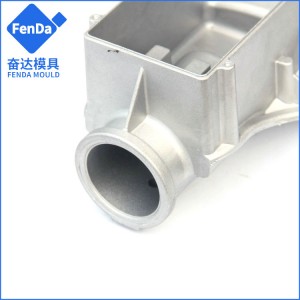

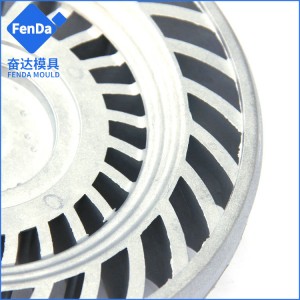

Chinese Custom LED Street Light Diecast Housing Aluminum Die Casting Parts

Factory Profile

Fenda is capable of designing and manufacturing tooling and fixtures for all our processes .

Simulation analysis helps our engineers design more efficient tooling. In-housing die casting tooling workshop assists in reaching customer lead time for manufacturing and verification.

The high pressure die casting process best illustrates our level of manufacturing capability. We have 7 advanced cold chamber die casting machines from 400T to 2000T in our die casting workshop, which allows us to meet demands in various aluminum die casting projects.

Our CNC machining center , equipped with 80 sets of high-speed/high-precision machining centers, and more than 20 sets of high-precision stir friction welding、surface treatment and other precision special machines . After machining, we can apply aesthetic ,functional and protective coating .

Why Choose Fenda as Your Die Casting Supplier

We focus on prototyping and production of industry-standard LED street light die casting housings and heat sinks. Our combination of manufacturing and engineering expertise and advanced technology ensures we deliver high-quality parts regardless of complexity. We also guarantee parts that stand the test of time while ensuring you reach your production goals and accelerating your LED lighting product development.

Strong Production Capacity

With our advanced technology and machines, our automotive product manufacturing capacity ensures every automotive part is of high quality and comes with the correct specification in dimension while performing excellently.

ISO Certified and IATF Certified

Fenda is ISO 9001 certified and IATF16949:2016 certified manufacturing company. We ensures you always receive high-quality automotive parts regardless of design complexity. Furthermore, we guarantee that we develop your products using internationally recognized best practices and that it meets all the required standards.

Fast Lead time

With our instant quotation system coupled with the perfect combination of advanced technology and top-draw professionals, Fenda produces and delivers your automotive parts as fast as possible. Getting your products faster will give more flexibility to improve or iterate them, thus outpacing your competitors during rapid shifts in the market

Fully Customizable

We follow your specifications on how you want your parts produced, considering your desired dimensions, material, and surface finish. We believe that developing a custom product makes your product unique and puts you ahead of the competition.