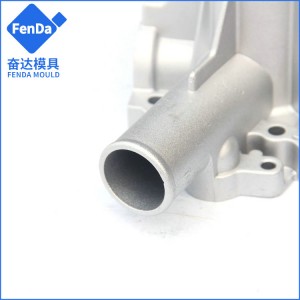

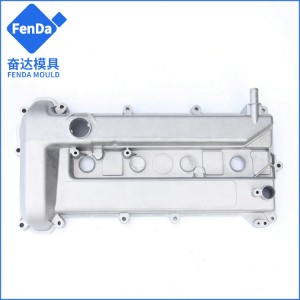

Automotive Water Pump Die Cast Housing Aluminum Die Casting Shell/Encloure/Case/Casing

Fenda Aluminum Alloy Die Casting

| Process

|

Drawing & Samples→Mould making→ Die casting → Deburring → Drilling and threading → CNC Machining → Polishing → Surface treatment → Assembly → Quality inspection → Packing →Shipping |

| Equipment | Cold chamber horizontal die casting machines 400T--2000T. CNC centers, EDM, WEDM, high-precision stir friction welding machine, CNC Milling machine ,CNC Drilling machine, CNC turning machine, CNC grinding machine,

CMM, Oxford-Hitachi spectrometer, Gas tightness tester |

| Material | Aluminum alloy ADC12, A360, A380 , AlSi12(Cu), AlSi9Cu3(Fe), AlSi10Mg and so on. |

| Surface

|

Trimming,Deburring,Polishing, Shotblasting,Sandblasting, Painting, Powder coating |

| Software Assistance | Pro-e/Solid work/UG/Auto CAD/CATIA |

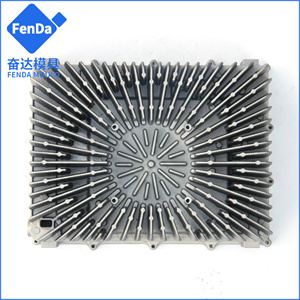

| Product application | Automotive Industry, Led lighting, Telecommunication, Textile machinery, Furniture, Power tool, other machinery industries. |

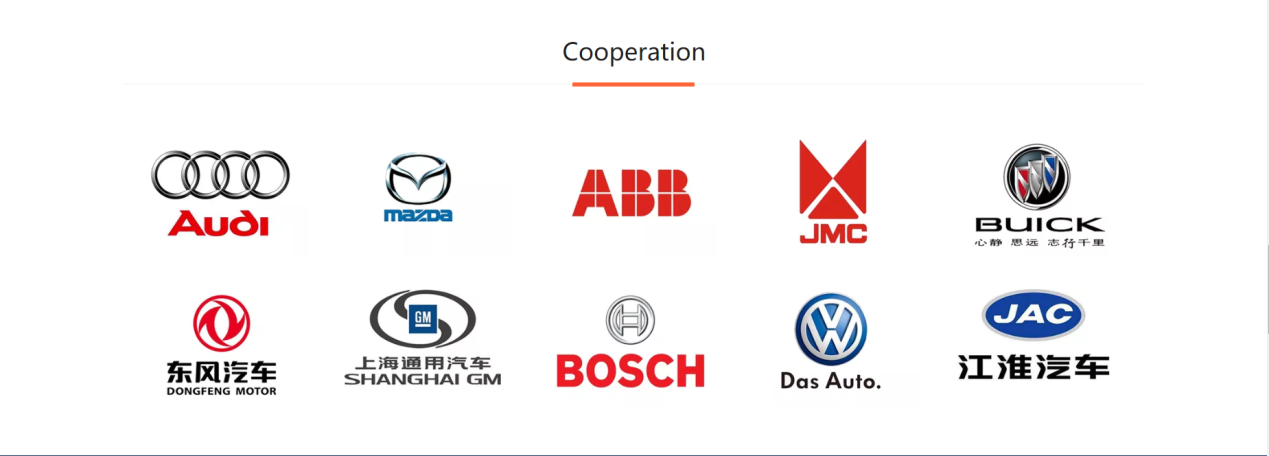

Factory Profile

Fenda, a China-based aluminum die casting manufacturer, proudly offers high-quality products in die casting manufacturing industry. From tooling design to casting parts manufacturing, CNC machining, finishing, and packaging, we provide comprehensive and cost-effective solutions for all your aluminum die casting needs.

* 1-Stop precision aluminum die casting solution provider

* 15+ years of experience, & 140 employees

* ISO 9001 & IATF 16949 certified

* 7 Die casing machines ranging from 400T to 2000T.

* 80+ high-speed/high-precision machining centers

Precision die casting solutions for the automotive sector

Fenda delivers precision results for the automotive industry. As a trusted partner, we specialize in high pressure aluminum die casting solutions for vehicle components and parts. We have been operating since 2006 and upgraded our facilities in 2020 to accommodate large and complex automotive projects. Our team has specialized industry knowledge and diverse experience in the transportation and automotive sectors. We specialize in accurate and cost-effective high pressure die casting for demanding automotive applications

Why Choose Fenda For Your Automotive Parts Projects

Fenda has over 17 years of experience assisting automotive manufacturers design cost-effective automotive components. When you cooperate with Fenda you can receive the following benefits from our die casting process:

Fenda is professional manufacturer with the ability to expand the die casting range, with die casting machines of 400-2000 tons of different tonnage. It can produce parts weighing 5g-20kg. The independent furnace of each die casting machine enables us to provide a variety of aluminum to meet the unique needs of customers.

Fenda can help consolidate your supply chain by offering the complete package of die casting services in addition to engineering support, mold design and troubleshooting, machining, and logistics.

Fenda is an ISO Certified and Die Casting Manufacturer and has extensive experience in designing and manufacturing aluminum parts to automotive quality specifications.

With presses ranging from large to small, we have the capability to manufacture automobile parts of many sizes.

We are ITAF 16949 certified and can provide part manufacturing for military and aerospace applications.