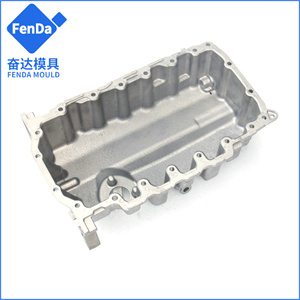

Automobile Engine Oil Pan Housing Aluminum Alloy Die Cast Housing Part

Product Description

| Product Name: | OEM Electric Automobile Oil Pan |

| Model No.: | To be customized |

| Material: | ADC12, A380 or as per request |

| Specification: | To be Customized |

| Chamber Structure: | Cold chamber Horizontal |

| Process: | High Pressure Die Casting + CNC machining |

| Inspection: | CMM, Oxford-Hitachi spectrometer, Gas tightness tester, Calipers etc |

| Surface Finishing | Sandblasting, sanding, deburring, CNC, powder coating, electroplating |

| Application: | Automotive |

| Certification: | ISO9001/IATF16949:2016 |

| Production Capacity: | 10000pcs/month |

| Place of Origin: | Ningbo, China |

Fenda Aluminum Die Casting & CNC Machining :

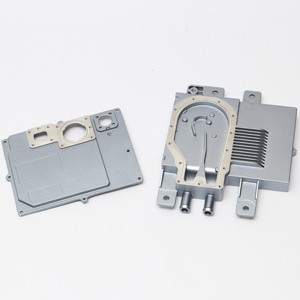

| Main Process | High Pressure Die Casting |

| Drawing format | AD, PDF, STP, DWG or Sample |

| Die casting machine type | From 400T to 2000T cold chamber horizontal die cast machines |

| Casting blanks tolerance | CT4-6 |

| Casting blank size | 2 mm-1500mm or according to customer requirements |

| Die casting materials | aluminum alloy, A360, A380, A383, AlSi10Mg, AlSi9Cu3, ADC3 and ADC12, or Customized |

| CNC machining | CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ stir friction welding |

| Machining Tolerance | 0.02MM |

| Machined surface quality | Ra 0.8-Ra3.2 according to customer requirement |

| Surface treatment | Polishing, Shot blasting, Sand blasting, Powder coating etc |

| Product application | Automotive Industry, Led lighting, Telecommunication, Textile machinery, Furniture, Power tool, other machinery industries. |

Factory Profile

Ningbo Fenda New Energy Technology Co., Ltd ( IATF 16949 registered factory), was established in 2006 with 15,000 square meters manufacturing facility. Located in Ningbo, China , it is dedicated to designing and manufacturing medium and large aluminum die casting molds and die castings for the Automotive, LED Lighting housing, Power Tools, and numerous mechanical applications. Our capabilities include tool design and manufacturing; casting; machining; finishing and assembly.

●1-Stop precision aluminum die casting solution provider

●15+ years of experience, & 140 employees

●ISO 9001 & IATF 16949 certified

●7 Die casing machines from 400T to 2000T.

●80+ high-speed/high-precision machining centers

●30 sets of high-precision stir friction welding、surface treatment and other precision special machines

●1 set of Zeiss CMM , 1 set of Eduard CMM, 1 set of industrial CT, 1 set of Oxford-Hitachi spectrometer and several sets of gas tightness testers.

With hard work, outstanding quality, and dependable service we have successfully and steadily grown over the years and have survived good and bad economic times along the way. Our main customers include ABB , GM, AUDI,MAZDA , BOSCH, BUICK and so on. For these customers we have designed and manufactured over hundreds sets of moulds these years. Most of our products have exported to USA, Germany, Italy, Netherlands and so on.

Contact us for your next project.

Why Choose Fenda for Your Aluminum Die Casting Parts ?

1.Die-casting Ability

Fenda is professional manufacturer with the ability to expand the die casting range, with die casting machines ranging from 400T to 2000 T. It can produce parts weighing 20g-40kg. The independent furnace of each die casting machine enables us to provide a variety of aluminum to meet the unique needs of customers.

2.Mold Design and Manufacturing in house

The in-house tooling shop allows us to do the die-casting mold design, mold Fabrication & mold maintenance in the same workshop. Our mold engineers will review your drawings and propose suggestions by mold flow analysis, which can help you prevent potential issues or risks that may happen in later production.

3. CNC Machining Ability

Fenda has an experienced and mature CNC machining team, more than 80 sets of high-speed/high-precision machining centers, and more than 20 sets of high-precision stir friction welding、surface treatment and other precision special machines . The minimum tolerance is controlled by 0.02mm to meet the needs of parts.

4.Most Competitive Price

We believe future development is based on any possible cooperation today, no matter how big the order is. Therefore, we control the profit at a very limited level.

We believe the future development lies in the current cooperation.

Our target is to produce high quality goods with very limited profit margin for the mutual benefits of both of us.

5.High quality

Process control and upfront engineering are the keys to guaranteeing high-quality castings. This is probably why Fenda exceeds the industry standards for internal scrap and failure rates. In summary, Fenda strives for Zero-Defects by continuously monitoring all processing and investing painstaking effort into tooling development and designs.