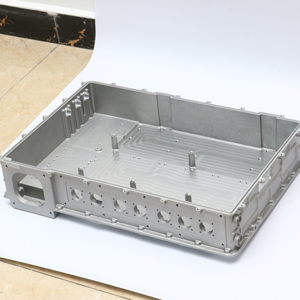

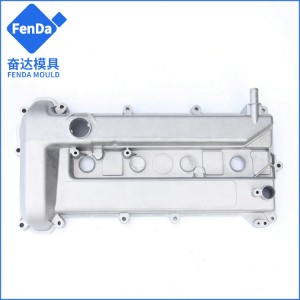

Aluminum Die Casting of Automobile Oil Pan Cover Housing Diecast Auto Parts

Basic Information

Product Name: Die Casting Automobile Oil Pan

Model No.: To be customized

Specification: 425*342*134mm

Weight: 3.5kgs

Material: ADC12

Application: Automobile

Chamber structure: Cold Chamber Horizontal

Main process: High Pressure Die Casting

Machining : CNC Machining

Tolerance: +/- 0.02mm

Certification: ISO9001:2015,ITAF16949:2018,

Place of Origin: Ningbo, China

Fenda Aluminum Die Casting & CNC Machining

| Mold material | H13, DVA, DIEVAR, 8407, 8418, W400, PH13 etc |

| Mold life | 50000 shots , or as per request |

| Product Material | Aluminum alloy ADC12, A360, A380 , AlSi12(Cu), AlSi9Cu3(Fe), AlSi10Mg and so on. |

| Surface Treatment | Polishing, Shotblasting,Sandblasting, Painting, Powder coating |

| Process | Drawing & Samples→Mould making→ Die casting → Deburring → Drilling and threading → CNC Machining → Polishing → Surface treatment → Assembly → Quality inspection → Packing →Shipping |

| Die casting machine | 400T/500T/630T/800T/1250T/1600T/2000T |

| Drawing format | step, dwg, igs, pdf |

| Certificates | ISO/IATF16949 :2016 |

| QC System | 100% inspection before package |

| Monthly Capacity | 40000PCS |

| Lead time | 25~45working days according to quantity |

| Payment terms | T/T |

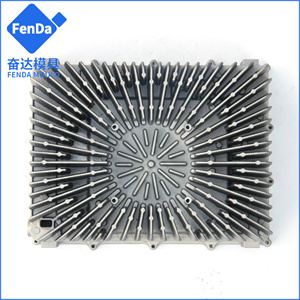

| Application | Automotive parts, Led light housing & heat sink , Electronic products body, Telecom chasis, cover, Power tool parts , Aerospace structure parts, Aluminum cooling plate. |

Factory Profile

Ningbo Fenda New Energy Technology Co., Ltd, formerly known as Ningbo Beilun Fenda Mould Co., Ltd, was established in 2006. It is a China-based aluminum die casting manufacturer, offers high-quality products in die casting manufacturing industry. From tooling design to casting parts manufacturing, CNC machining, finishing, and packaging, we provide comprehensive and cost-effective solutions for all your aluminum die casting needs.

Our factory is located in Beilun District, Ningbo and has a plant area of 15,000 square meters, more than 140 employees. We have our independent mould workshop and CNC machining workshop with 80 sets of high-speed/high-precision machining centers, 4 sets of EDM machines,

6 sets of WEDM machines, and more than 20 sets of high-precision stir friction welding、surface treatment and other precision special machines .In our die casting workshop there are 6 sets of aluminum die casting machines ranging from 400T to 2000T.

Fenda provides superior quality aluminum die casting parts and components for a wide range of industries including automotive, led lighting, telecommunication, machinery, medical, plumbing, watering, mining, petrochemical, electrical, energy, aerospace, submarine and others. We are proud to work with some of the world’s top automotive brands as below:

Contact us for your next project.

Why Choose Fenda for Your Aluminum Die Casting Parts ?

We focus on prototyping and production of industry-standard automotive parts. Our combination of manufacturing and engineering expertise and advanced technology ensures we deliver high-quality parts regardless of complexity. We also guarantee parts that stand the test of time while ensuring you reach your production goals and accelerating your automotive product development.

Strong Production Capacity

With our advanced technology and machines, our automotive product manufacturing capacity ensures every automotive part is of high quality and comes with the correct specification in dimension while performing excellently.

Instant Quotation

Our instant and intelligent quotation platform makes your manufacturing experience seamless and stress-free. To start your automotive part projects, you can upload your CAD files to our quotation platform to get an instant quote. Besides, we have an efficient order management and tracking system, which keeps you updated on your order.

IATF16949:2016 certified

Fenda is a IATF16949:2016 certified manufacturing company. We ensures you always receive high-quality automotive parts regardless of design complexity. Furthermore, we guarantee that we develop your products using internationally recognized best practices and that it meets all the required standards.

Fully Customizable

We follow your specifications on how you want your parts produced, considering your desired dimensions, material, and surface finish. We believe that developing a custom product makes your product unique and puts you ahead of the competition.

Fast Lead time

With our instant quotation system coupled with the perfect combination of advanced technology and top-draw professionals, Fenda produces and delivers your automotive parts as fast as possible. Getting your products faster will give more flexibility to improve or iterate them, thus outpacing your competitors during rapid shifts in the market