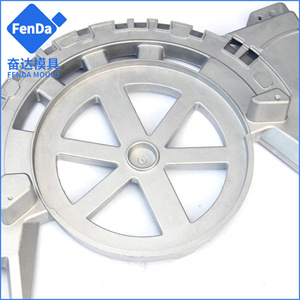

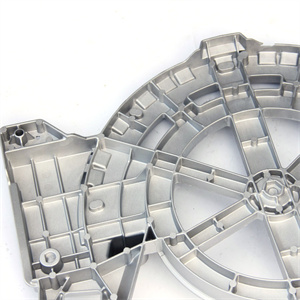

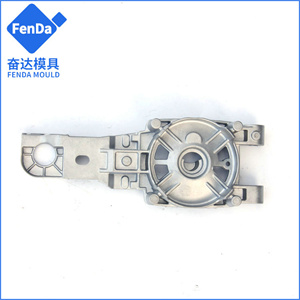

Aluminum Die Cast Parts Power Tool Bracket/Base/Housing/Cover Die Casting Components

Fenda Custom Die Casting Parts

| Mold material | H13, DVA, DIEVAR , 8418, , W400, PH13 etc |

| Mold life | 50000 shots , or as per request |

| Product Material | Aluminum alloy ADC12, A360, A380 , AlSi12(Cu), AlSi9Cu3(Fe), AlSi10Mg and so on. |

| Surface Treatment | Polishing, Shotblasting,Sandblasting, Painting, Powder coating |

| Process | Drawing & Samples→Mould making→ Die casting → Deburring → Drilling and threading → CNC Machining → Polishing → Surface treatment → Assembly → Quality inspection → Packing →Shipping |

| Die casting machine | 400T/500T/630T/800T/1250T/1600T/2000T |

| Drawing format | step, dwg, igs, pdf |

| Certificates | ISO/IATF16949 :2016 |

| QC System | 100% inspection before package |

| Monthly Capacity | 10000PCS |

| Lead time | 25~45working days according to quantity |

| Payment terms | T/T |

| Product Application | Automotive Industry, Led lighting,Telecommunication, Textile machinery, Furniture, Power tool, other machinery industries. |

Factory Profile

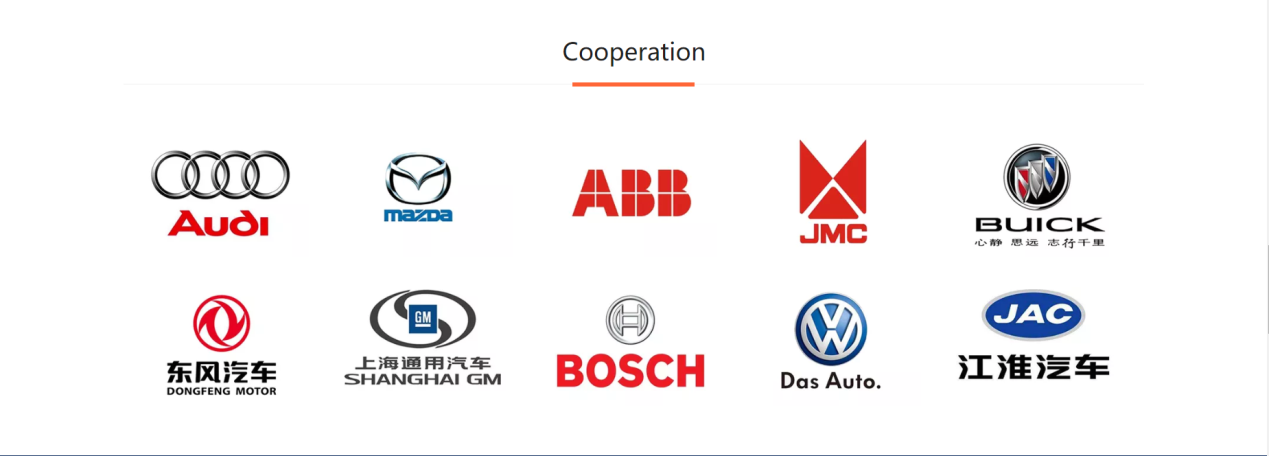

Ningbo Fenda New Energy Technology Co., Ltd ( IATF 16949 registered factory), was established in 2006 with 15,000 square meters manufacturing facility. Located in Ningbo, China , it is dedicated to designing and manufacturing medium and large aluminum die casting molds and die castings for the Automotive, LED Lighting housing, Power Tools, and numerous mechanical applications. Our capabilities include tool design and manufacturing; casting; machining; finishing and assembly. Our annual capacity for mold is 200 sets and annual capacity for die castings are over 1500 tons.

●1-Stop precision aluminum die casting solution provider

●15+ years of experience, & 140 employees

●ISO 9001 & IATF 16949 certified

●7 Die casing machines from 400T to 2000T.

●80+ high-speed/high-precision machining centers

●30 sets of high-precision stir friction welding、surface treatment and other precision special machines

●1 set of Zeiss CMM , 1 set of Eduard CMM, 1 set of industrial CT, 1 set of Oxford-Hitachi spectrometer and several sets of gas tightness testers.

With turn-key solutions, a team of experts, and a commitment to delivering superior-quality products and services, we help you save costs and run your projects more smoothly. Contact us for your next project.

Our advantage:

|

1 |

Around 20 years die casting mold making experience, certificated with IS09001 & IATF 16949 and with skilled and professional workers. We are the expert at Strong engineering, exquisite workmanship, products of various materials high precision request and complex shapes |

|

2 |

More than 30 countries export experience ensure our technical team are able to offer tailor-made service with International standard toward to our customers |

|

3 |

We are big company group investing a lot on hardware and software facilities. We have advanced and high precision equipment and machines as well as latest mold design software and mold flow analysis software |

|

4 |

Work with many world class brands, Very high quality in the industry. |

|

5 |

Big factory guarantees our plenty production capacity and our short lead time and quick response capability; |

|

6 |

Familiar with material industry, to use high quality materials to be sure long life time and excellent hot runner system and cooling system to increase production efficiency; |

|

7 |

We believe future development is based on any possible cooperation today, no matter how big the order is. Therefore, we control the profit at a very limited level. Our target is to produce high quality goods with very limited profit margin for the mutual benefits of both of us |