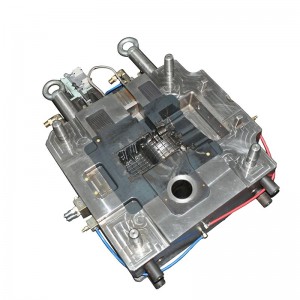

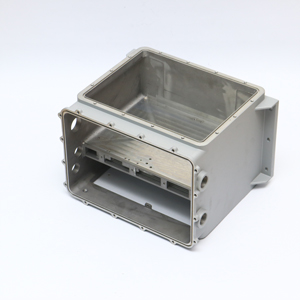

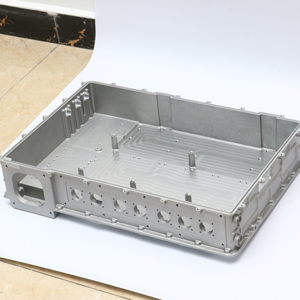

Aluminum Alloy Die Casting Enclosure Telecom Die Cast Housing/ Enclosure

Communication Equipment Die Casting

Fenda offers die cast solutions for all types of telecommunications applications.

Our ISO 9001: 2015 Certified manufacturing facility is fully equipped with aluminum die casting ranging from 400 to 2000 tons and 80 CNC machining centers giving us the flexibility to react to quick changes in engineering revisions. In addition, we have a full array of finishing and assembly options to give you a turnkey solution for your project.

The enclosures and components we manufacture can withstand water, dust and shielding from RMI/RFI. These components meet the most stringent standards, regardless of your market or your location, Fenda is your trusted supplier for die cast components.

Fenda Custom Aluminum Die Casting Products

| Mold material | H13, DVA, DIEVAR, 8407, 8418, W400, PH13 etc |

| Mold life | 50000 shots , or as per request |

| Product Material | Aluminum alloy ADC12, A360, A380 , AlSi12(Cu), AlSi9Cu3(Fe), AlSi10Mg and so on. |

| Surface Treatment | Polishing, Shotblasting,Sandblasting, Painting, Powder coating |

| Process | Drawing & Samples→Mould making→ Die casting → Deburring → Drilling and threading → CNC Machining → Polishing → Surface treatment → Assembly → Quality inspection → Packing →Shipping |

| Die casting machine | 400T/500T/630T/800T/1250T/1600T/2000T |

| Drawing format | step, dwg, igs, pdf |

| Certificates | ISO/IATF16949 :2016 |

| QC System | 100% inspection before package |

| Monthly Capacity | 40000PCS |

| Lead time | 25~45working days according to quantity |

| Application | Automotive parts, Led light housing & heat sink , Electronic products body, Telecom housing, cover, Power tool parts , Aerospace structure parts, Aluminum cooling plate, Die casting Heat sinks |

Why Choose Fenda For Your Aluminum Die Casting Parts ?

1.Mold Design and Manufacturing in house

The in-house tooling shop allows us to do the die-casting mold design, mold Fabrication & mold maintenance in the same workshop. Our mold engineers will review your drawings and propose suggestions by mold flow analysis, which can help you prevent potential issues or risks that may happen in later production.

2.Die-casting Ability

Fenda is professional manufacturer with the ability to expand the die casting range, with die casting machines of 400-2000 tons of different tonnage. It can produce parts weighing 5g-40kg. The independent furnace of each die casting machine enables us to provide a variety of aluminum to meet the unique needs of customers.

3. CNC Machining Ability

Fenda has an experienced and mature CNC machining team, more than ten imported processing centers and lathes, and its own processing brand PTJ Shop is one of the top ten small and medium-sized processing manufacturers in China. It provides reliable precision for processing. The minimum tolerance is controlled by 0.02mm to meet the needs of parts.

4.Most Competitive Price

We believe future development is based on any possible cooperation today, no matter how big the order is. Therefore, we control the profit at a very limited level.

We believe the future development lies in the current cooperation.

Our target is to produce high quality goods with very limited profit margin for the mutual benefits of both of us.

5. Quality Inspection System

Fenda pays special attention to the quality control of the mass production process and has established a complete quality inspection process and system. All products are fully inspected or constructed in accordance with the standards. Testing equipment includes: spectrometer, stretching Testing machine, CMM three-coordinate, pass-stop gauge, parallel gauge, various calipers, etc., to achieve the control ability of the quality system.